Farmers in India face lot many challenges and farming as a profession has become unviable and dying. Hence, Innovation is the key to overcome these fundamental challenges and most importantly sustainability of agriculture. At Mahindra Tractors, our commitment to create positive change in the communities is demonstrated by our recent nomination for the AEGIS Innovation Award. Our submission, titled “Agriculture Tractor: Automation & Connected,” speaks about the cutting-edge technology launched for the farmers across the globe in the name of ROBOJA and MYOJA. These two revolutionary solutions are results of our relentless pursuit to overcome the limitations of traditional farming methods by transforming the Agricultural landscape.

The Genesis of ROBOJA and MYOJA

As the global population continues to rise, the area under cultivation has been decreasing, resulting in increased stress on agricultural productivity to meet growing needs. Farmers in India face numerous challenges, including mechanization, availability of skilled manpower, urban shift, and increased revenue to agricultural households from non-agricultural streams. There is also lesser participation of women in mechanization, and the younger generation is increasingly reluctant to choose agriculture due to the strenuous manual work involved.

Conventional farming methods, while effective, demand substantial physical and cognitive effort from operators, especially during repetitive activities like headland management. Headland operations involve turning the tractor along with its implement at the end of a field, requiring the simultaneous use of both hands and legs. This labor-intensive process demands precise coordination to turn the wheels, lift implements, disengage the PTO, and manage braking, all without causing soil compaction. Current scenario demands skill to have higher productivity but availability of skilled manpower is becoming a huge challenge due to this arduous work requirements.

Take vineyards as an example: one acre of land requires about 20 turns, and an operator covering 3-5 acres per day performs a minimum of 60 to a maximum of 100 turns daily. While these numbers don’t explicitly convey the fatigue, the toll on operator health is significant. The higher effort needed to apply brakes and the soil compaction due to wheel slippage during turns limit overall productivity. Many operators in India rely on their own judgment when operating tractors, and only a few achieve higher productivity based on their experience in setting the draft while using draft implements.

Due to above mentioned Drudgery, Tractor operation is traditionally seen as a Male dominant one and Current tractors by design demand high efforts to operate. Efforts needed to operate brake pedal can be as high as 60 kg based on the load. This explains the reason for need of gender-neutral design and elimination of fatigue experienced by the tractor operators for increased operational efficiency and productivity.

Engineers in Mahindra Tractors brainstormed to solve the above-mentioned fundamental challenges of Effort, Skill & fatigue and embarked on the mission of creating solutions that orbit shifts Comfort, Productivity, Precision and Lower Cost of Operation. This journey culminated in OJA tractors with technologies of ROBOJA and MYOJA.

ROBOJA – Delivering Advanced Automation & Smart Applications To Transform Precision

For supreme efficiency and precision, ROBOJA or the Automation Pack, eliminates the need for extensive manual intervention while operating a tractor. With category first features it allows OJA tractors to transmit power to additional equipment that do not have their own engine or power source ensuring efficient and precise farming. ROBOJA achieves the automation through adoption of Electronic Depth & Draft control system (EDDC). Main features of ROBOJA are Auto PTO, Auto Implement Lift and Auto One Side Braking.

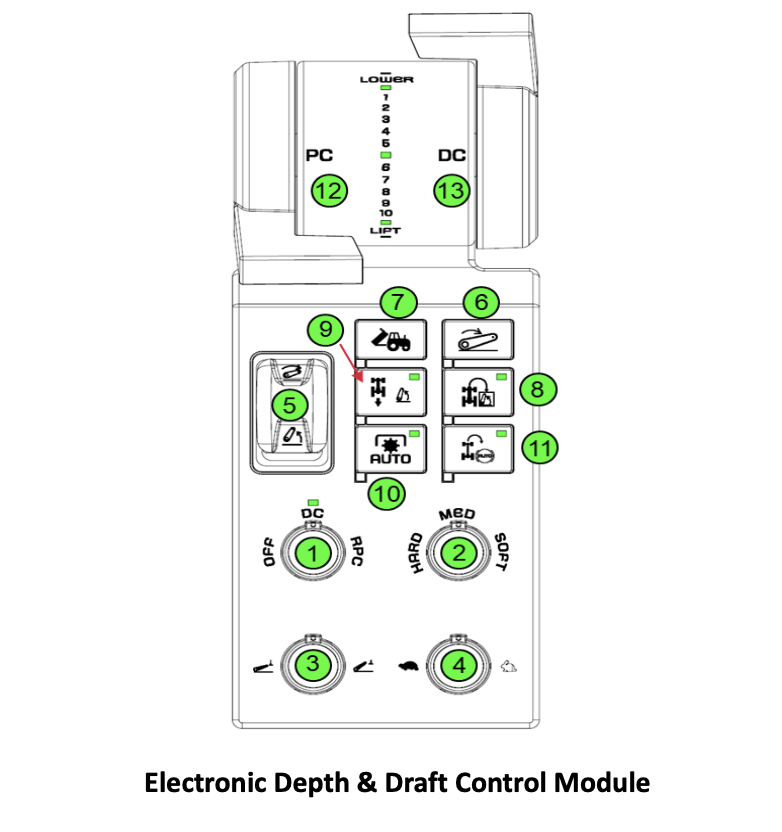

EDDC of ROBOJA includes integration of EDDC module, Sensors and Actuators with Indigenously designed & developed Farm Machinery Control Unit (FMCU) to achieve automation. FMCU acts as the brain of this automation while Electronic Depth & Draft Control Module provides the HMI for the various automation delivered through ROBOJA.

Electronic Depth & Draft Control Module

| S.No | System | Features | Functions |

| 1 | Hydraulic | Mode selector(OFF/DC/Sprayer) | Comfort & Productivity |

| 2 | Sensitivity Control for draft (Hard-Normal-Soft) | Productivity | |

| 3 | Height setting | Comfort | |

| 4 | Lowering speed control | Comfort | |

| 5 | Quick Lift(EQL) | Comfort & Productivity | |

| 6 | Quick Lift Momentary | Comfort & Productivity | |

| 7 | Tipping trailer | Comfort | |

| 8 | Auto Implement Lift during Turn | Comfort & Productivity | |

| 9 | Auto implement Lift during Reverse | Comfort & Productivity | |

| 10 | PTO | Auto PTO cut-off during Turn & Reverse | Comfort & Productivity |

| 11 | Brake | Auto One side braking | Comfort & Productivity |

| 12 | Hydraulic | Position control (PC Lever) | Comfort & Productivity |

| 13 | Draft control (DC Lever) | Comfort & Productivity |

The Auto PTO feature grants farmers with the ability to effortlessly engage the PTO with a simple touch of a button. The Electric Wet PTO clutch ensures smooth functionality and offers immense ease of use. Additionally, the Auto PTO can be automatically turned ON or OFF while turning and reversing of a tractor further enhancing convenience during field operations, while also providing the benefit of saving on costs of pesticides and fertilizers.

The Auto Implement Lift function enables automatic lifting and lowering of implements while turning and reversing, further streamlining the tractor’s capabilities. Electronic depth & draft control hydraulic systems ensures precise and efficient farming operations.

Auto One-Side Braking allows intelligent brake application on one side during turns, eliminating management of both steering and braking simultaneously, helping tighter turning radius and preventing the risk of skidding or loss of control during turns.

ROBOJA has resulted in significant value proposition to Farmers across Dryland and wetland operations.

Tangible & immediate benefits witnessed are fuel savings, lower service cost, pesticide savings, excellent drivability. Specifically, the automation allowed the operator’s right leg and right hand to be free during headland turns, which conventionally requires simultaneous use of the brake pedal, clutch pedal, steering wheel, and hydraulic controls. This reduction in manual effort significantly has reduced operator fatigue and drudgery involved in the operations enabling tractors to be used for longer duration. Quick response time of EDDC, Auto one side braking and auto PTO cut off, Auto implement lift system in combination has resulted in reduced load on the engine and thus reduced fuel consumption. Due to auto PTO cut off at the headland turns in sprayer application, spray of pesticides at unintended places have been avoided to save the pesticides. Automatic lift of implements and auto PTO cut off during lifting has reduced mechanical wear and tear of the mechanical components and hence savings in maintenance has been noted apart from Fuel savings.

Testing was conducted in varying soil conditions and for 3 major applications. 60% of the test duration was allotted to Sprayer applications with remaining 40% distributed between Cultivator and rotary Tiller. Out of Total savings, 47% of savings were from Fuel considering all 3 defined applications – spraying, cultivation, and rotary tilling, the following fuel efficiencies were observed for the respective applications.

- Spraying: 64.8 liters/year saved

- Cultivation: 16.2 liters/year saved

- Rotary Tilling: 24.84 liters/year saved

In total, the automation system resulted on an average annual fuel savings of approximately 105.84 liters leading to a cost saving of 10,584 INR.

Additionally, the automation of PTO cut-off during spraying operations has resulted in pesticide savings, further reducing operational costs by 6,000 INR annually for the test duration completed. Numbers realized by the operators vary based on the area covered.

The reduction in service and maintenance requirements due to less wear and tear of manual components has resulted in additional savings of 5,900 INR per year. Increased coverage of the tractor and potential savings on health has not been tabled as those are intangible. Reduction in effort and over all body fatigue has also enabled the operators to work for longer duration. Objective of Achieving Gender Neutral design has been achieved with Roboja Technology.

The automation system has improved overall productivity by 11%, as it allowed operators to perform tasks more efficiently with fewer errors and reduced downtime.

System has resulted in automatic corrections and uniform depth coverage and optimal soil engagement. This has boosted the speed of operations and contributed to a more uniform and higher-quality output in crop management.

Beyond the environmental impact, enhanced ergonomics provided by the system, also played a critical role in improving job satisfaction and reduction of operator fatigue over extended periods.

In conclusion, the integration of EDDC-based automation into agricultural tractors has proved to be an important step forward in countering the current challenges faced by the farmers.

MYOJA – Delivering Exceptional Productivity & Efficiency

The MYOJA or the Telematics Pack empowers farmers with advanced control over their tractors, via a mobile phone application. The feature provides real-time data on location, fuel usage and tractor health. This proactive approach enhances maintenance planning and ensures farmers are always in control, with a constant eye on the health and functionality of their tractors.

GPS Live Location helps track the live location of the tractor, and enables geofencing, ensuring lesser dependency on the operator.

Service Alerts plays a crucial role in keeping the farmer informed about their tractor’s service requirements through proactive service reminders, ensuring timely and efficient servicing.

The Critical Alerts feature provides immediate notifications in the event of major engine-related issues, while ensuring monitoring and detection of tractor abuse or misuse.

The Diesel Monitoring feature offers visibility into the fuel level and effectively prevents instances of fuel theft.

The Coverage & Trip Calculator provides effortless tracking of the tractor’s performance, across both field work and haulage conveniently, ensuring effortless tracking of performance.

A Step Towards Sustainable Agriculture

At Mahindra Tractors, we strive for Enriching Farmer’s lives through transformation of Farming. ROBOJA & MYOJA not only improves farming efficiency and productivity but also plays a crucial role in advancing sustainable development, addressing key global challenges, and enhancing the welfare of farming communities.

Looking Ahead

Being nominated for the AEGIS Innovation Award is a great honor and confirmation of our efforts to our purpose of Transform Farming. We have just begun and We are continuously working on enhancing ROBOJA and MYOJA, incorporating feedback from farmers and leveraging the latest technological advancements. Our goal is to democratize Technological solutions & make it accessible to farmers across the globe, helping them overcome challenges and drive positive change in their lives.